Spark Plug Wire 101

The purpose of spark plug wires is to carry electricity from the ignition coils to the spark plug. This causes the spark plug to spark and ignite the fuel mixture in the combustion chamber. The ignition coils on the 2004-2006 Pontiac GTO can carry up to 40,000 volts of electricity. The spark plug wire assures that all the intended volts are delivered to the spark plug and nowhere else other than the spark plug.

Spark Plug Wire Construction

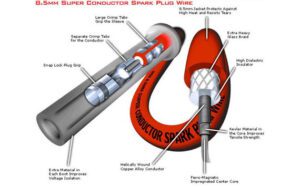

Spark plug wires are made of a conducting material to carry electricity from the ignition coils to the spark plugs. This works much like any electrical wire found in today’s homes. The difference is the volts are much higher and must be carried safely so as not to interrupt other electronic components on the vehicle. Almost all plug wires are constructed using similar components: a central core, conductive suppression layer insulator, fiberglass braid, and an outer silicone jacket.

The two major factors of choosing a spark plug wire are the wire’s resistance and the wires’ ability to prevent Electromagnetic interference (EMI) or radio frequency interference (RFI).

- Resistance: Rated in ohms-per-foot, resistance is the ignition wire’s tendency to resist the flow of the electric current. Wires with higher ohms-per-foot ratings will allow less current to flow from the spark source to the plugs. This can affect engine performance and fuel economy in a negative way.

- Electro-magnetic interference (EMI) or radio frequency interference (RFI): As the higher charges of today’s electronic ignitions are moved through the wires, an electromagnetic field is created around the wire. This field can interfere with sensitive electronic devices and create noise that can be heard through the radio, and even affect sensors. This is referred to as EMI or RFI and can wreak havoc, especially in sensitive radio communications.

Companies will use different conducting materials for the central core of their products. All of them of course claim theirs is better than the competition. The central core material is the main part of the spark plug wire that will deliver the volts to the spark plug. Below are the most popular style conducting materials used:

- Carbon Core: This is the common OEM-style core used on most modern vehicles. It offers excellent RFI suppression, but also creates more resistance than other styles. In addition, carbon core breaks down more quickly than other materials, so they require relatively frequent replacement.

- Solid Core: Solid core spark plug wires typically utilize stainless steel or copper, which conducts electrical current very well. For that reason, solid core wires have lower resistance than other wires to get maximum energy to the plugs. Unfortunately, solid core offers very little EMI/RFI suppression, so they’re not suited for electronic ignition systems or vehicles with sensitive communications equipment. You will find solid core wires used on race cars and cars not utilizing a lot of electronic components. Upon further research, you will be lucky to even find solid core spark plug wires anywhere. These were mostly used on vehicles in the 1950s and 1960s and primarily for alcohol and nitro-burning cars using no electronic components. Solid Core spark plug wires are not used for any of today’s vehicles including race cars.

- Spiral Core: Spiral core spark plug wires incorporate an alloy—usually consisting of stainless steel, copper, and tin—wrapping the core to suppress EMI/RFI while maintaining low resistance. As with everything, there is a delicate balance. More wire coils around the core will reduce noise but raise the resistance of the wire. Many of the high-performance spark plug wires are spiral core. And again, companies will use different variations of the central core material used.

Stock/Factory Spark Plug Wires vs. High-Performance Spark Plug Wires

The spark plug wires from the factory (stock) will be carbon core wires. This offers the least amount of radio frequency interference and will not interrupt the vehicle’s electronic components. They deliver the proper amount of spark to the spark plug and do exactly what they are designed to do. This style of spark plug wire is prone to wear and tear and can begin arcing if the wires show age. These wires do not hold up to the engine heat well. This style of spark plug wires is intended to be replaced and will not last the life of the vehicle. These styles of wires will absolutely work without fail as long as the spark plug wires are in good condition.

The difference between the factory and high-performance spark plug wires is durability. To be honest, the factory AC Delco spark plug wires found on the Chevrolet LS engines which are used by the 2004-2006 Pontiac GTO are the nicest and most durable stock wires I have ever seen. The stock/factory spark plug wires are carbon core and offer the best protection against EMI and RFI interference. The downside is they also have the highest amount of electrical resistance. Even as nice as the factory wires are, they still do not last and can become brittle from heat. The most common problem is the factory spark plug wires will break apart right where the wire meets the spark plug wire boot (attaches to the spark plug) on the spark plug side.

High-Performance spark plug wires will be spiral core wires and are much more durable. The central core of these wires can be a variety of materials depending on which companies spark plug wire they are. The outer layer is usually much thicker than the factory wires, making them much more durable to withstand engine heat. This style of wire is also much less prone to arcing due to its thicker outer shell and durable construction. Most High-Performance spark plug wires for street applications will also have RFI and EMI suppression to prevent electrical interference with the vehicle’s electronic components.

Which spark plug wires should I use on my 2004-2006 Pontiac GTO?

This has been a debate for years. Hopefully, I can clear this up a bit from my research. Spark plug wires are designed to take the electrical current from the coils to the spark plug, that is it. There is no performance gain from using expensive spark plug wires over the factory stock spark plug wires. If you gain horsepower from changing spark plug wires, that means the spark plug wires you replaced were not working correctly and needed to be changed anyway. There is however a difference in construction and durability.

That factory or stock spark plug wires over time can become brittle and crack. The rubber insulation surrounding the wires themselves can develop small cracks in them just from time (being old) or from the heat from the engine and exhaust manifolds. These cracks can cause the spark to actually arc. Spark plug wire arcing occurs when the spark from the wire finds another way out of the wire besides the intended route of travel to the spark plug. The spark will find another closer metal object on the engine as a ground and jump to that, such as an exhaust manifold bolt. Now the spark from the coils is not completely going to the spark plug. Some spark will be going to the exhaust manifold bolt in my example, and some spark will go to the spark plug. This can cause a misfire since the spark plug will not be receiving the full jolt of spark coming from the ignition coils. Factory spark plug wires also may not be able to hold up to the heat from high-performance exhaust manifolds, called “Headers”. The factory spark plug wires could melt, and cease to deliver spark to the spark plug, also causing a misfire.

High-Performance Spark Plug Wires for the most part are more durable than factory spark plug wires. They can also offer less resistance to electricity than the stock spark plug wires while suppressing EMI and RFI interference. They are also constructed in a way that the wires can withstand heat, as well as reduce any possibility of arcing, delivering the entire jolt of electricity from the ignition coil directly to the spark plug. The factory spark plug wires are designed to do this as well. Will changing to high-performance spark plug wires improve the performance of your engine? Absolutely not. The engine is designed for the full amount of spark to be delivered, even with the factory spark plug wires.

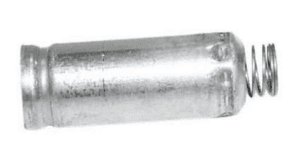

- Stock/Factory: The AC Delco factory spark plug wires are very good. I would not use any other stock spark plug wires other than the factory replacement. They do an excellent job of delivering spark and suppressing all RFI and EMI frequencies. Be advised, if you have exhaust headers on the vehicle, use the factory metal spark plug boot heat shields on the wire. These wires may need to be replaced in as little as 20,000 miles. The drawback of these types of wires is they are carbon core which tends not to last very long. Also, the carbon core used as the central core of the spark plug wire offers the most RFI and EMI suppression of any other central core material, but it also comes with the most electrical resistance. This means the flow of the electrical current is not as strong as it could be.

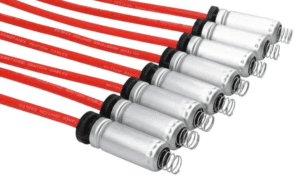

- High Performance: There are many companies that make high-performance spark plug wires, that would be an excellent replacement for the stock spark plug wires. They will be more durable and withstand the engine heat much better than the factory wires. They will also deliver the most amount of spark with the least amount of resistance, while suppressing RFI and EMI frequencies, protecting all the vehicle’s electronic components. The majority of these types of spark plug wires are spiral cores. These spark plug wires can last as long as 50,000 – 100,000 miles based on their durability and ability to withstand heat.

| The Answer: A quality name-brand, high-performance spark plug wire would be the best choice, especially if replacing the stock spark plug wires. High-performance spark plug wires that are spiral core will offer the least amount of electrical resistance as well as suppress RFI and EMI frequency. You do not need to buy the most expensive spark plug wires on the market. For street applications, a $400 set of spark plug wires is not going to deliver a better spark or add any more horsepower than an $80 set of spark plug wires. Just remember you are paying more for durability rather than performance. The ignition coils deliver the spark, the spark plug wires carry the spark, and the spark plug uses the spark to ignite the fuel mixture in the combustion chamber. To get more technical, the vehicle’s computer tells the ignition coils how many volts to send through the spark plug wire based on engine speed and air-fuel mixture. |

Spending more on high-performance spark plug wires that can withstand engine and exhaust manifold heat is well worth it, especially for vehicles equipped with exhaust headers. Also switching to a high-performance spark plug wire that prevents arcing and suppresses EMI and RFI interference with the least amount of electrical resistance makes perfect sense. The 2004-2006 Pontiac GTO is loaded with electronic equipment. It is very important to use the correct spark plug wire that suppresses EMI and RFI frequencies that can damage electronic components, especially when we are dealing with 40,000 volts.

Recommended Spark Plug Wires

I have put together a list of spark plug wires that I know will work for the 2004-2006 Pontiac GTO vehicles with no fitment issues. Switching to a high-performance spark plug wire set will save you time and money in the long run. They will last longer than the factory carbon core spark plug wires and offer just as much and possibly better transfer of spark from the ignition coils to the spark plugs. The factory AC Delco factory spark plug wires are a very good choice, and will easily handle the job of delivering spark to the spark plug. But be advised the carbon core construction of the factory spark plug wires means you will have to replace them sooner than a high-performance spark plug wire set. If you need to replace your spark plug wires, which you will need to eventually, I recommend the following spark plug wire sets:

| Note: 2004 Pontiac GTO uses different part numbers for the spark plug wire sets than the 2005 and 2006 models. The 2004 Pontiac GTO has different ignition coils and placement of the coil brackets than the 2005 and 2006 GTO with the LS2 engine. The 2005 and 2006 Pontiac GTO spark plug wires are slightly longer and the 2004 Pontiac GTO spark plug wires will not properly fit the 2005 and 2006 GTO models. |

2004 PONTIAC GTO SPARK PLUG WIRE SETS

| BRAND | TYPE/DESCRIPTION | PART NUMBER |

| AC Delco |

Carbon Core |

748mm |

MSD |

Spiral Core |

32819 |

| NGK |

Spiral Core |

RC-GMX090 |

2005-2006 PONTIAC GTO SPARK PLUG WIRE SETS

| BRAND | TYPE/DESCRIPTION | PART NUMBER |

| AC Delco | Carbon Core AC Delco Professional Spark Plug Wire Sets are engineered with strength-enhancing fiberglass and high-temperature silicone insulators. These spark plug wires are a premium aftermarket offering that covers over 96% of domestic vehicles on the road today. |

9748rr |

ACCEL |

Spiral Core ACCEL Extreme 9000 ceramic wires are the cure for burnt spark plug boots. These wires provide excellent energy delivery while delivering the highest level of RFI/EMI suppression. They are ideal for custom engines, boats, and RVs. |

9070C |

MSD |

Spiral Core The MSD 8.5 mm super conductor wire is the performance wire. Incredibly low resistance without electronic interference. The low resistance results in less loss of spark energy so more reaches the spark plug. |

32829 |

There are also many other companies that make high-performance spark plug wires. The wire sets mentioned above are the ones I know work well with no fitment issues. I have personally used these spark plug wire sets and can verify they do fit and will perform as expected.

| Note: The MSD 8.5mm high-performance spark plug wire set, part # 32819, will show up on most after-market auto parts stores as fitting the 2004-2006 Pontiac GTO. This plug wire set will only fit the 2004 Pontiac GTO and can not be used on the 2005 and 2006 Pontiac GTO equipped with the LS2 engine. The 2005 and 2006 GTO need a slightly longer spark plug wire because of the use of the LS2 ignition coil and the placement of the coil brackets. If you use the MSD 32819 spark plug wire set on a 2005 or 2006 GTO, the spark plug wire will barely reach. Any vibration or movement can pop the metal terminals on the spark plug wire off of the connection to the ignition coils or spark plug, causing a misfire. Do not use MSD 8.5mm 32819 spark plug wire set on 2005 or 2006 Pontiac GTO. |

Other Companies that sell high-performance spark plug wires:

- Taylor

- Dragon Fire

- Hinson Motorsports

- Granatelli

- F.A.S.T.

BATTLING HEAT

If heat on the spark plug wires is a concern, or your spark plug wires are prone to melting from touching the exhaust manifolds, there is a solution. Switching to ACCEL Ceramic spark plug wires is an excellent choice. The ceramic spark plug boots will never melt and can directly lay right on the exhaust manifold and never get damaged. Another choice would be to use the factory AC Delco Heat Shields on the spark plug boots themselves as pictured here:

Another choice could be to use spark plug wire sleeves. These can be used with or without metal heat shields. You can find these sleeves easily by doing an internet search. They come in colors and are extremely easy to install. Many have purchased these from eBay as well as other online retailers. The sleeves simply slide over the spark plug wire protecting it from heat, as pictured here:

| Note: I hope you found the information contained on this website useful. Many hours of time and research have gone into building this website. Please feel free to donate to Mark Quitter Racing. Donations will be used to pay for website services or for any other practical use per your request which can be filled out on the PayPal donation link. There is no minimum amount, and your contribution is greatly appreciated. Donate here. |